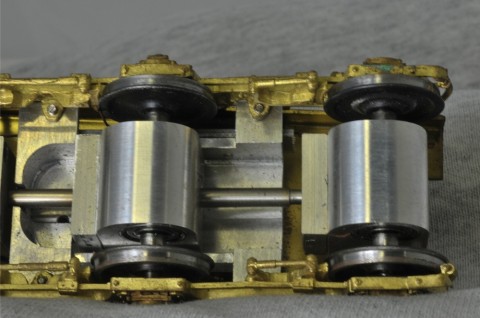

The “Super Stealth” drive system.

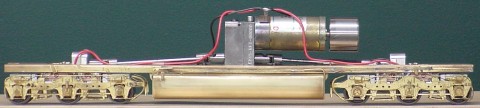

The drive system used in these models will be manufactured by our parent company, ECS Fabrication, Inc. It is the latest and final variant of the ECS drive system and offers powerful and totally silent running capability. All moving parts on this drive are made of metal – no plastic. All parts are made and assembled in the USA at the ECS facility. This system uses ball bearings throughout the entire system. There are NO BUSHINGS. Journal boxes will also be ball bearing equipped. Please note that this drive system is not a “tank drive” and that there are no visible components between the fuel tank and the truck as on some competitors’ models, thus adding to the realism of these locomotives. Components are concealed within the body as seen in the chassis picture below.

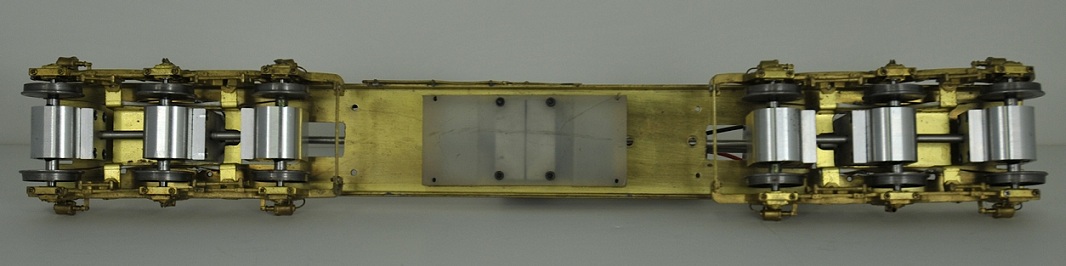

The pictures of locomotives shown on this page are drive conversions – other manufacturer’s locomotives that have been custom fit with our drive system. Prices vary per number of axles and wheel options, so please email with any questions about pricing. Conversions will be equipped as seen in these pictures. Only Midwestern Model Works locomotives will be equipped with fully detailed trucks with authentic looking traction motors, transoms, bolsters, brakes, brake rigging, ducting, etc. The drives in the SD45s will be made in great quantity and the models will be made specifically to fit these drives removing the ‘custom’ installation and facilitating the use of this system in the Midwestern Model Works models without the ‘custom’ cost. We are still performing drive conversions on existing locomotives. Email for information and lead times if you have interest in one of our conversions.

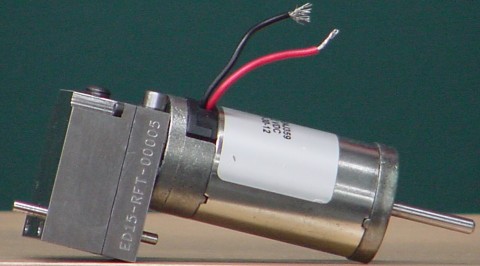

This drive will begin to move on just 0.5 volt on clean track and will creep slowly and smoothly along. Since the drive has almost no resistance, the motor will draw minimal amperage. Maximum amperage on the motor will never be reached because it is IMPOSSIBLE to stall this drive. At 4.0 VDC this system will spin all twelve wheels with more than 10 pounds of weight on the chassis. These units are all CNC machined and the reduction boxes are sealed to hold oil. There is a geared oil pump (like in an automobile engine) to keep a constant flow of heavy gear oil flowing over all gears at all times while running and a dipstick to check oil level if the model is subject to extremely heavy and frequent running conditions. (See customer comments at bottom of page)

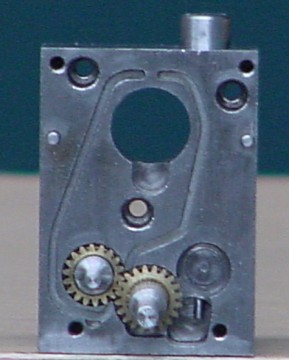

To the left is a new Super Stealth gearbox with a dipstick installed. Another dipstick is pictured leaning against the gearbox to show what one looks like when removed.

This picture shows the gears that make up the oil pump. They have no propulsion function and are dedicated strictly for pumping oil. Note the oil passages leading to the top of the gearbox. From there, oil passes through a gasket and into passages in the other half of the gearbox and directly onto the gears it is intended to lubricate. Also visible is the end of the dipstick in the lower right corner of the oil sump area. The main sump area is much larger and in the bottom of the other half of the box.

All reduction boxes are serial numbered. The reduction box has a final gear ratio of 15:1 allowing for scale speeds from creeping along all the way up to 80 MPH.

The towers and transaxle boxes are made from 6061-T6 aluminum.

They are strictly a 1:1 ratio to avoid the use of undersize gears that can not take the abuse that an “O” Scale railroad can inflict upon them. A high quality, low viscosity grease is used to keep the transaxle gears lubricated for life.

A closer inspection of the truck reveals 0.145 wheels. The ball bearings in the journals are barely visible on a few of the axle ends. These sideframes have not been modified so that the brake shoes align with the wheels.

The following shots show a model with a custom machined aluminum bolster and 0.114 wheels. Even though the wheels are true scale 0.114s, the unit is still gauged at 5′. Note the proximity of the brake shoes to the wheel tread. This procedure will be followed on our SD45 project for added realism. The same attention to detail will be present on any units that are built to Proto48 standards.

Although this locomotive chassis is shown to have the .114 wheels, it is still gauged at Standard O. We are offering the .114 wheels and substantially narrowed truck sideframes as an option to the .145 NMRA standard wheels. These wheels will be installed on all Proto48 models and ONLY those Standard O models in which the reservation holder has specifically requested them. We would like to emphasize the importance of track work should the decision to use the .114 wheels be made. Albeit they are actual scale, they have smaller flanges and narrower wheel tread and are not as forgiving on track that is not in gauge and does not transition into curves and grades smoothly. If the track is suitable, this really adds to the appearance and realism of the model.

Although this locomotive chassis is shown to have the .114 wheels, it is still gauged at Standard O. We are offering the .114 wheels and substantially narrowed truck sideframes as an option to the .145 NMRA standard wheels. These wheels will be installed on all Proto48 models and ONLY those Standard O models in which the reservation holder has specifically requested them. We would like to emphasize the importance of track work should the decision to use the .114 wheels be made. Albeit they are actual scale, they have smaller flanges and narrower wheel tread and are not as forgiving on track that is not in gauge and does not transition into curves and grades smoothly. If the track is suitable, this really adds to the appearance and realism of the model.

This shot shows a .175 wheel (old NMRA standard), a .145 wheel (new NMRA standard) and a .114 wheel (true 1/4 inch = 1 foot scale) from left to right respectively for comparison. Note the difference in flange height and thickness.

Customer comments about the “Super Stealth” diesel drive:

(Received 3/20/15) Hello Erik,

I just ran your new transmission box and the drive is absolutely great. I ran a train up a 2% grade at about 7.5 volts with 14 brass cars and 18 atlas reefers – all this with a little over an amp. The gearbox is totally quiet at any load or speed. You can now install a QSI sound decoder and it will be the real thing. Your older transmission also had plenty of torque but spur gears are just a little noisy. This is, without a doubt, the most totally silent diesel ever put on the market. The engine zips around the layout with 32 cars with a breeze. The engine starts with that load at about 2.5 volts. Just great!

Dieter Boehme

Thanks for your input Dieter!

We’ll post more as they come in.